Is modulation a good indicator of quality?

Posted on December 16, 2015

LED lighting is the replacement of the traditional incandescent and fluorescent bulbs and tubes. LED lighting is better in efficiency and energy saving, lasting much longer than traditional lighting and can give a much better quality lighting environment.

However, within the industry there is the issue of periodic modulation or flicker. Here is brief look at modulation and if it is an indicator of quality.

What is modulation and flicker?

Flicker is a constant fluctuation of light output due to the electricity being delivered through alternating current. It can potentially cause people to have migraines and eye strain.

How is flickering tested?

The first and most commonly used metric is percent flicker. It indicates the average amount of modulation, or reduction, in light output over a single on–off cycle. A source with 100 percent flicker would indicate that, at some point in its cycle, it produces no light, while a completely steady light would have zero percent flicker.

Manufacturers are aware of standards and regulations regarding the issue of flickering. There is an international IEEE standard which is called Modulation.

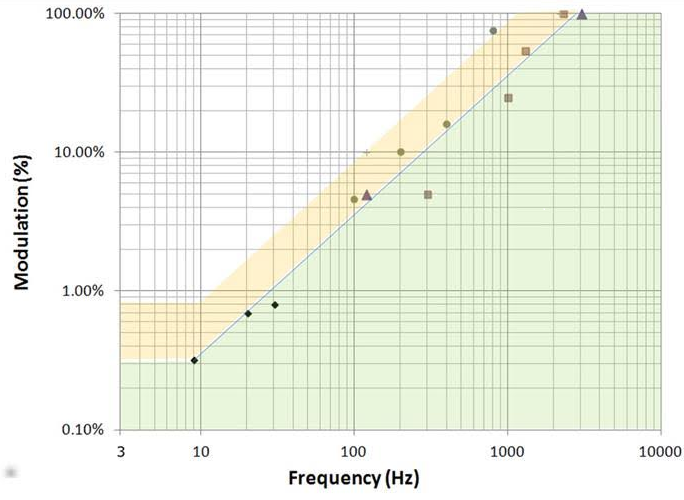

We can see from the modulation graph, in the green area, it is no Effect Zone. In the yellow area, it is Safety Zone. In the White Area, it is Risky Zone.

Modulation is defined as the difference between maximum and minimum luminance divided by the sum of maximum and minimum luminance.

For example here is a Sedna product with the following results:

(1396-1214)/(1396+1214)= 6.97%.

As the power supply is working under 50Hz 230V, through the rectifier bridge, the actual output currency is 100Hz. You can see under 8%, the product is within the safety zone.

LED Flicker does it mean products are inferior?

Some manufacturers will claim that their lighting is better by showing no flickering on a camera phone. Yet, this is no indication of the quality of the product. Even when lighting is well within the safe zone of modulation there still may be flickering on a camera phone.

Furthermore, by reducing the flicker to the extent of not being visible on a phone, this cannot be a cost effective method for manufacturing LED lighting and may be a trade-off of potentially decreasing system reliability.

Therefore by testing data & having certificates of modulation are a true reflection and indicator of quality.

There are other causes of flickering, such as compatibility issues with dimming and control circuitry. Also, random, intermittent flickering could be an indication of some other problem in the lighting system such as loose wiring and interconnections. Possible problems with the quality of the electrical supply can also result in power fluctuations. If those causes are suspected, it is important to investigate further to prevent any potential safety hazards.

It is key for designers to work with lighting manufacturers to identify a compatible system and test that system firsthand under the driver and dimming settings expected in the final installation.